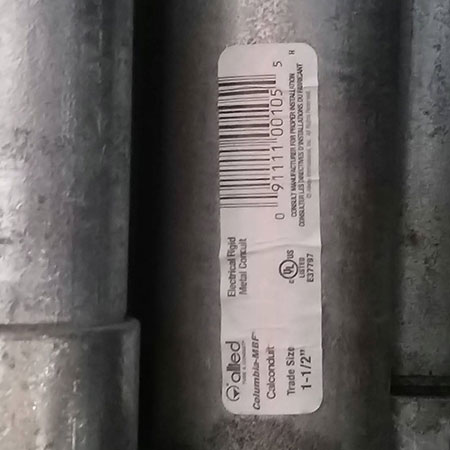

Galvanized Rigid Steel Conduit

As a premier manufacturer and supplier of Galvanized Rigid Steel Conduit, our company is dedicated to providing durable and reliable solutions for electrical and mechanical protection. Our conduits are designed to offer superior protection against physical damage, corrosion, and environmental factors, making them an ideal choice for both indoor and outdoor applications. Crafted with precision, our product ensures that your wiring systems are safely enclosed and protected, meeting the highest industry standards.

Galvanized Rigid Steel Conduit

Model - E1

Galvanized steel rigid conduit

Products are widely used in automobiles, ships, shipbuilding, electric power industry, electronic parts, mechanical engineering, railways, bridges, aviation and other fields.

Product Features

1.Manufactured to meet the specifications laid out in ANSI C80.1 and UL6.

2.Highest strength steel offers longetivity and value under the most demanding environments.

3.The heaviest and thickest walled conduit, yet posseses superior ductility for cutting, bending and welding.

4.Clean even interior facilitates smooth continuous raceways for easy wire pulling.

5.Hot Dipped Galvanised widely regarded as the most superior galvanising protection against corrosion.

6.Supplied precision threaded, with a thread protector on one end and a coupling on the other.

7.RMC is supplied in standard length of 10ft (3.05m). Available from 1/2″ to 6″.

8.RMC couplings, elbows and nipples are available from 1/2″ to 6″.

Application Advantages

RMC is manufactured to ensure absolute functionality in a variety of demanding environments. Be it indoor or outdoor, exposed or concealed, dry or wet locations. Or even in hazardous locations when in accordance with National Electric Code (NEC) Article 344.

1.Reusability for future additions or replacement of conduits.

2.Non-combustibility reduces hazard from fire.

3.Built-in grounding capabilities eliminate the need for supplemental grounding conductors.

4.Steel conduit acts as an Electromagnetic Interference (EMI) shield.

Products are widely used in automobiles, ships, shipbuilding, electric power industry, electronic parts, mechanical engineering, railways, bridges, aviation and other fields.

Product Features

1.Manufactured to meet the specifications laid out in ANSI C80.1 and UL6.

2.Highest strength steel offers longetivity and value under the most demanding environments.

3.The heaviest and thickest walled conduit, yet posseses superior ductility for cutting, bending and welding.

4.Clean even interior facilitates smooth continuous raceways for easy wire pulling.

5.Hot Dipped Galvanised widely regarded as the most superior galvanising protection against corrosion.

6.Supplied precision threaded, with a thread protector on one end and a coupling on the other.

7.RMC is supplied in standard length of 10ft (3.05m). Available from 1/2″ to 6″.

8.RMC couplings, elbows and nipples are available from 1/2″ to 6″.

Application Advantages

RMC is manufactured to ensure absolute functionality in a variety of demanding environments. Be it indoor or outdoor, exposed or concealed, dry or wet locations. Or even in hazardous locations when in accordance with National Electric Code (NEC) Article 344.

1.Reusability for future additions or replacement of conduits.

2.Non-combustibility reduces hazard from fire.

3.Built-in grounding capabilities eliminate the need for supplemental grounding conductors.

4.Steel conduit acts as an Electromagnetic Interference (EMI) shield.

Our

As a leading exporter of steel conduits, we are committed to delivering products that meet the rigorous demands of global markets. Our stringent manufacturing processes and quality control measures ensure that every conduit we produce is consistent in quality and performance. With our extensive experience and dedication to excellence, we have earned a reputation as a trusted partner for industries around the world.

When you choose our conduits, you’re investing in a product that combines strength, reliability, and durability. Our conduits are backed by our commitment to customer satisfaction and our ability to provide tailored solutions that meet the unique requirements of your projects. Trust us to deliver the high-quality conduits you need to ensure the safety and longevity of your electrical systems, all with the quality assurance that has made us a leading name in Taiwan.

Galvanized Rigid Steel Conduit

is manufactured from high-quality steel and coated with a thick layer of galvanization to prevent rust and corrosion. This makes our conduits particularly suitable for use in harsh environments, such as industrial facilities, commercial buildings, and outdoor installations. Available in a range of sizes and specifications, our conduits are versatile and can be customized to meet the specific needs of your projects, ensuring that you always have the right product for your application.As a leading exporter of steel conduits, we are committed to delivering products that meet the rigorous demands of global markets. Our stringent manufacturing processes and quality control measures ensure that every conduit we produce is consistent in quality and performance. With our extensive experience and dedication to excellence, we have earned a reputation as a trusted partner for industries around the world.

When you choose our conduits, you’re investing in a product that combines strength, reliability, and durability. Our conduits are backed by our commitment to customer satisfaction and our ability to provide tailored solutions that meet the unique requirements of your projects. Trust us to deliver the high-quality conduits you need to ensure the safety and longevity of your electrical systems, all with the quality assurance that has made us a leading name in Taiwan.

Enquiry Now

Products List

Galvanized Rigid Steel 90° Elbow

Products are widely used in automobiles, ships, shipbuilding, electric power industry, electronic parts, mechanical engineering, railways, bridges, aviation and other fields.

Product Features

1.Manufactured to meet the specifications laid out in ANSI C80.1 and UL6.

2.Highest strength steel offers longetivity and value under the most demanding environments.

3.The heaviest and thickest walled conduit, yet posseses superior ductility for cutting, bending and welding.

4.Clean even interior facilitates smooth continuous raceways for easy wire pulling.

5.Hot Dipped Galvanised widely regarded as the most superior galvanising protection against corrosion.

6. Galvanized Rigid Metal Elbows meet UL6 and ANSI C80.1

5" and 6" size Elbows available only in Rigid Galvanized Steel and Aluminum.

Stainless Steel 316 Elbows available upon request

11-1/4°, 15°, 22-1/2°, 30° and 60° Elbows also available

Application Advantages

RMC is manufactured to ensure absolute functionality in a variety of demanding environments. Be it indoor or outdoor, exposed or concealed, dry or wet locations. Or even in hazardous locations when in accordance with National Electric Code (NEC) Article 344.

1.Reusability for future additions or replacement of conduits.

2.Non-combustibility reduces hazard from fire.

3.Built-in grounding capabilities eliminate the need for supplemental grounding conductors.

4.Steel conduit acts as an Electromagnetic Interference (EMI) shield.

Galvanized Rigid Conduit (GRC) Finishing:

• Hot-dip galvanized for excellent corrosion resistance

• High strength ductile steel for long life and easy bending

• Listed to Safety Standard UL 6

• Manufactured in accordance with ANSI C80.1

• Available in sizes 1/2 (16) - 6 (155)

Outside Diameter Tolerance:

± 0.015 inch (0.38mm) for trade sizes 1/2" through 1-1/2"

± 1% for trade sizes 2" through 6"

Wall Thickness Tolerance:

± 12.5%

Length Tolerance:

± 0.25 inch (6.35mm)

CONDUIT NIPPLES

Conduit Nipples are used to extend a length of threaded rigid or IMC conduit. Fabricated from rugged galvanized steel for low conductivity and high corrosion resistance and to ensure secure connections and preserve integrity and longevity. UL listed.

Products are widely used in automobiles, ships, shipbuilding, electric power industry, electronic parts, mechanical engineering, railways, bridges, aviation and other fields.

Product Features

• NPT thread

• High corrosion resistance

Applications

• Use to extend a length of threaded Rigid or IMC conduit Standard

UL certified

Material

• Galvanized steel

Reducing Bushings

Reducing Bushings reduce the size conduit hubs; smooth and rounded integral bushing offers conductor protection. Fabricated from strong and long lasting steel or high grade malleable iron. Steel sizes from 1/2" by 3/8" to 2" by 11/2"; malleable iron available in sizes from 2 1/2" by 1" to 4" by 3 1/2".

Products are widely used in automobiles, ships, shipbuilding, electric power industry, electronic parts, mechanical engineering, railways, bridges, aviation and other fields.

Product Features

• Rounded bushing protects conductor

• NPT thread

Applications

• Dry location use only

• Use to reduce the entry size of a run of threaded conduit

Standard Material

• Steel

Standard Finish

• Zinc plated

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文